John Leed

March 3, 1978

STANDARD PRACTICE INSTRUCTIONS - SPI-14

Subject: Propeller Shaft Alignment Procedure

Purpose: To prevent premature failure of all. seals, gears and bearings; loss of RPM; vibration, or gear noise caused by a bent prop shaft or misalignment between the transmission output shaft and shaft coupling.

Reference: A.B.Y.C. P-6; Chrysler Installation Manual 81-770-7795; OMC Propeller Shaft Slignment Procedure

1. Before attempting final alignment:

A. Check shaft coupler pilot diameter and output flange pilot bore diameter. There should be no more than a light resistance between the coupler pilot and the output flange pilot bore during assembly. See Figure 1, (Typical)

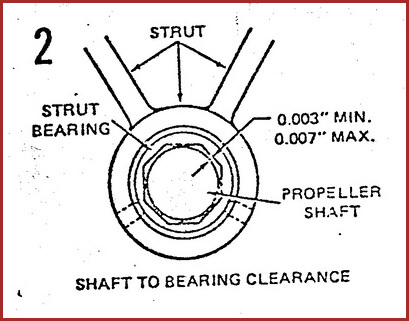

B. Check strut tearing to shaft clearance. Shaft diameters from 3/4" to 1-3/4" must have a total minimum clearance of .003" and a total maximum clearance of 0.007". See Figure 2.

C. Check the shaft coupler to propeller shaft fit. The coupler should be a light press fit and may be heated slightly to allow easier assembly. A coupler which is a few thousandths of an inch too large for a particular shaft will distort as the set screws are tightened. See Figure 3.

D. Check strut alignment.

The shaft haft must be centered in the shaft log and the strut bearing. The packing gland and hose should be removed from the shaft log for this check. See Figure 4.

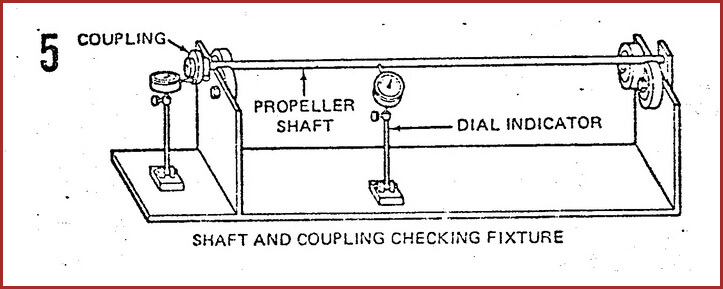

*E. Check the propeller shaft, propeller shaft coupling, and transmission output flange for straightness. The fixture (Figure 5) is inexpensive and very reliable for checking the shaft and coupler. Check at quarter points and center: See Figure 5. For maximum permissible variation see A.B.Y.C. P-6-3.42.

*Note: This step may be omitted as long as shafts are assembled and being checked by outside vendor.

2. Engine Alignment:

A. When the propeller and propeller shaft coupling are installed and the shaft located fore and aft by locating the propeller relative to the strut, the shaft should be blocked or shimmed in the center of the shaft log. Next, the engine is located visually so that the engine half of the propeller shaft coupling is coaxial with and its face parallel to the shaft half of the coupling. At this point, the engine should be firmly on all of its mounts, and provisions should made for fine adjustment, using built in screw jacks, wedges or shims.

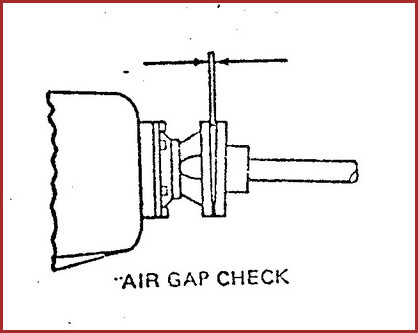

At this point, one of the engine mounts closest to the coupling can be fastened to the engine bed. Engage the coupling pilot diameters fully and check the faces for parallelism with a feeler. If there is a gap allowing more than .005" feeler per inch of face diameter (.002" for 4" coupling, .003" for 6" coupling, etc.) to enter between the faces at any point, shift the opposite end of the engine in the direction needed to close the gap, pivoting on the fastened engine mount.

3. Flange Squareness Check:

A. To check the squareness of the coupling face to the shaft center line, first align the engine with the shaft. Next, keep the engine coupling stationary and turn the propeller shaft 90°, 180° and 270° and recheck the faces for being parallel. If they still are parallel, the face is square with the shaft. If they are not, but the gap is increased 50% or less, re-align the alignment with the shaft in four position, 90° apart, relative to the engine. If the gap is now less than .003" for a 41N coupling, .0045" for a 6" coupling, .006" for an 8" coupling, etc., it is safe to securely fasten all engine mounts, recheck the alignment, and if it has not changed, fasten the coupling halves together. Since a boat may not he perfectly rigid, the alignment should always be given its final check and the coupling bolted together in the water When a boat is to be hauled out of the water, its coupling should be unbolted to prevent bending the shaft.