Page 1

November 6, 1972

J. Ressler

J. Scott

STANDARD PRACTICE INSTRUCTION #32

Subject: Jam Nuts -- Use on Propeller Shaft

Problem: Proper installation of the Jam Nut is vitally important to the quality of our product. Improper installation of the jam nut on the shaft could cause loosening of the hex nut and possible loss of propeller.

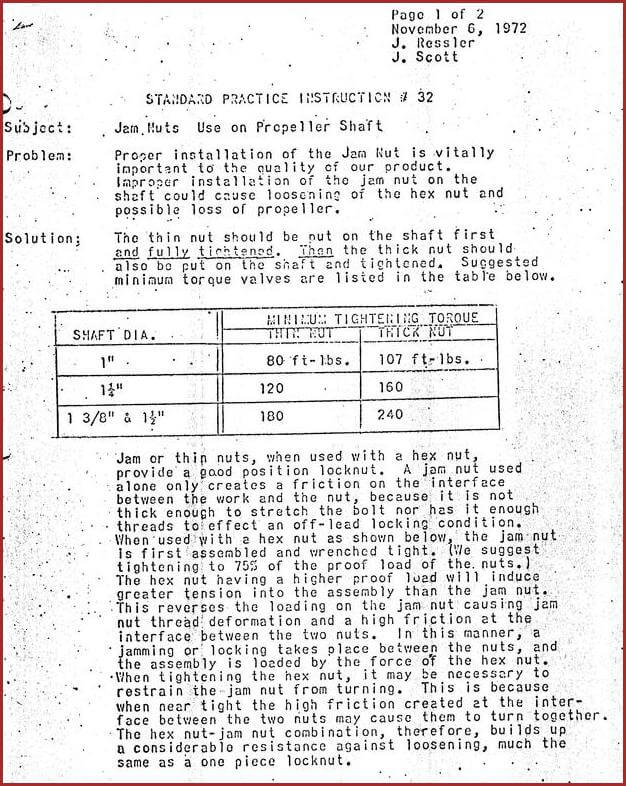

Solution: The thin nut should be nut on the shaft first

and fully tightened. Then the thick nut should also be put on the shaft and tightened. Suggested minimum torque values are listed below.

| Shaft Diameter | Minimum Tightening Torque (ft-lbs) |

|---|

| Thin Nut | Thick Nut |

|---|

| 1" | 80 | 107 |

| 1.25" | 120 | 160 |

| 1.375" & 1.5" | 180 | 240 |

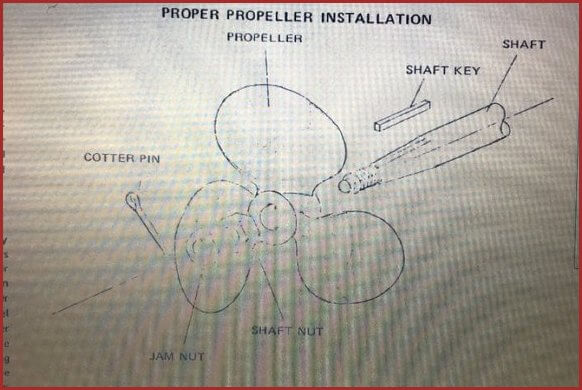

Jam or thin nuts, when used with a hex nut, provide a good position locknut. A jam nut used alone only creates a friction on the interface between the work and the nut, because it is not thick enough to stretch the bolt nor has it enough threads to effect an off-lead locking condition. When used with a hex nut as shown below, the jam nut is first assembled and wrenched tight. (We suggest tightening to 75% of the proof load of the nuts.) The hex nut having a higher proof load will induce greater tension into the assembly than the jam nut. This reverses the loading on the jam nut causing jam nut thread deformation and a high friction at the interface between the two nuts. In this manner, a jamming or locking takes place between the nuts, and the assembly is loaded by the force of the hex nut. When tightening the hex nut, it may be necessary to restrain the jam nut from turning. This is because when near tight the high friction created at the interface between the two nuts may cause them to turn together. The hex nut-jam nut combination, therefore, builds up a considerable resistance against loosening, much the same as a one piece locknut.